A drum motor is the drive unit for a conveyor belt where the electric motor, gearbox and bearings are enclosed in a tubular shell.

- What maintenance does a drum motor require?

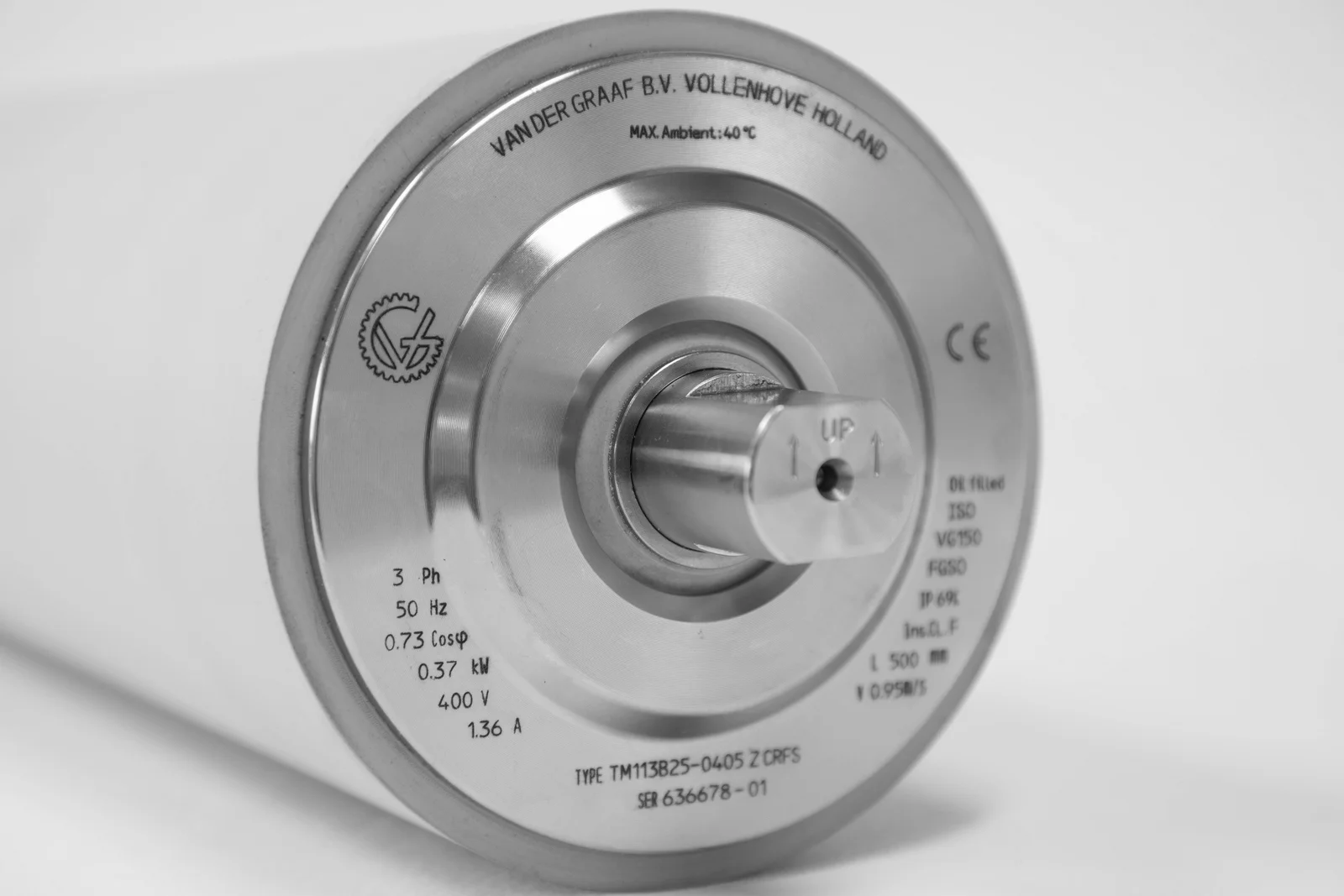

No maintenance is required. Van der Graaf drum motors are factory-filled with high quality oil, which only needs to be changed after 25,000 hours of operation.

- Can a drum motor be controlled by an inverter?

Because the drum motor is oil-cooled, it can be easily controlled by an inverter without the risk of overheating. The control range is 20 to 80 Hz (for 4-pole motors).

- Does Van der Graaf have drum motors with a fixed direction of rotation?

All Van der Graaf drum motors are suitable for both left hand and right hand rotation. Van der Graaf drum motors can be fitted with a backstop non-reversing bearing to prevent either left or right rotation. An electro-mechanical brake can also be incorporated so that the drum motor can operate in both directions of rotation, but can also be blocked if required.

- Can Van der Graaf drum motors operate without a conveyor belt?

In general, our drum motors can be used in applications without a conveyor belt (e.g. in pallet conveyors or with a brush). If your application is without a belt, please contact us just to be sure.

- What global ‘standards’ are available?

Van der Graaf drum motors are CE certified, but also available in UL and CSA C US. Our motors are also available according to Atex zone 22.

- What voltages/frequencies are available?

Van der Graaf can provide windings for different voltages and frequencies, worldwide.

- What if an incorrect voltage is supplied?

All Van der Graaf drum motors from TM100 up to and including the TM800 have drum shells that are bolted on. This means that our motors are easy to dismantle for maintenance or repair. In the event of a malfunction or wear and tear, most local winding companies can repair your drum motor without any difficulty. Parts will normally be available anywhere in the world within 24 to 48 hours.